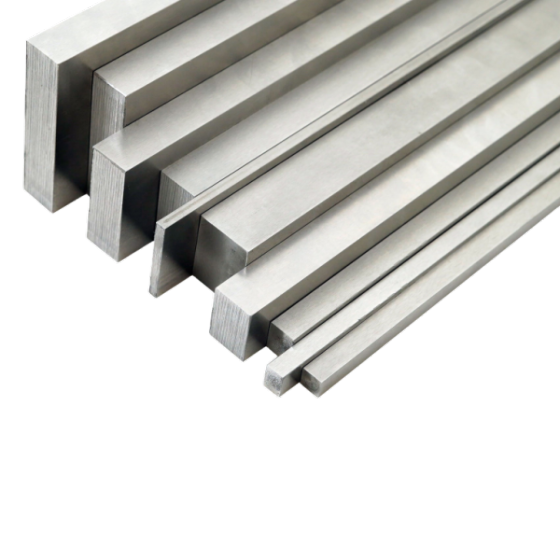

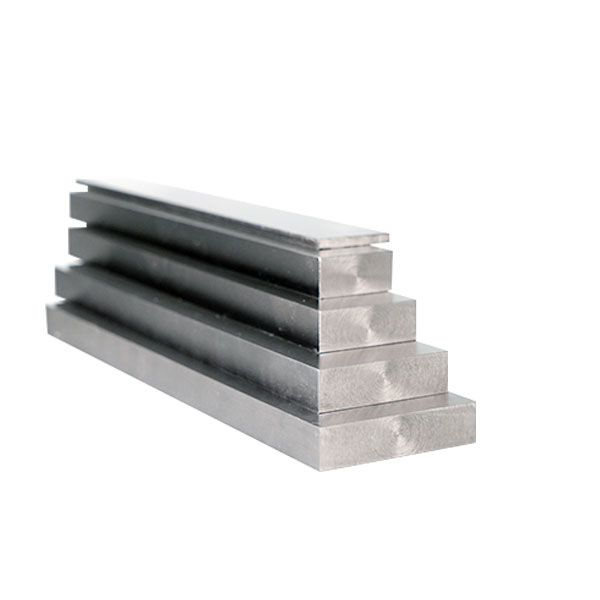

Cold Drawn Bearing Steel Flat Bar

1. Cold Drawn Bearing Steel Flat Bar has high contact fatigue strength, which can well extend the service life of the bearing.

2. Cold Drawn Bearing Steel Flat Bar has strong wear resistance and high hardness.

3. Cold Drawn Bearing Steel Flat Bar has strong anti-rust performance and strong processing performance.

- Information

- Download

Description of Cold Drawn Bearing Steel Flat Bar:

The production of bearing steel pipe refers to the refining of bearing steel and chromium-free bearing steel. Production of tubes for the manufacture of bearing rings. Bearing steel pipes are high-dimensional precision pipes, which are mostly produced by hot rolling with two or three-roll cross-rolling extension machines, and those with smaller specifications need to be produced by cold rolling and cold drawing. Using long steel pipes instead of one-piece forging or round bar turning to produce bearing sleeves can save metal, simplify the bearing manufacturing process and reduce the cost of bearings.

The main purpose of Cold Drawn Bearing Steel Flat Bar:

SUJ2 cold drawn flat bar can be used as a finished material for hoop irons, tools and mechanical parts such as building frame structures and escalators.

Specifications of Cold Drawn Bearing Steel Flat Bar:

| Product Name | Cold drawn bearing steel flat bar |

| Materials Grade | 52100, GCr15,GGr15SiMn, SUJ2 |

| Standard | AISI, ASTM,JIS, GB,EN |

| Size | 8x10~50x60mm |

| Length | 3000mm-12000mm or as client's request |

| Tolerance | ±1% |

| Technology | Cold drawn,Hot rolled |

| Packing | Seaworthy packing |

| Payment Term | L/C,T/T(30% deposit) |

| Lead Time | 20 days or to be negotiated |

| MOQ | ≤1000kgs |

| Supply Ability | 10000 Ton Per year |

Pros of Cold Drawn Bearing Steel Flat Bar:

1. 52100 cold drawn flat bar has high and uniform hardness, wear resistance and high elastic limit.

2. GCr15 cold drawn flat bar is made of high-carbon chromium steel, and is generally used to manufacture balls, rollers, bearing rings and other accessories. GGr15SiMn cold drawn flat bar has excellent wear resistance, balanced chemical composition, and strict requirements for the internal distribution of various substances, especially the arrangement of carbides. It is considered to be one of the strictest in all kinds of steel production.

3. SUJ2 cold drawn flat bar has good impact toughness and fracture toughness, can withstand heavy loads, run at high speed, and is durable.

About the production process of Cold Drawn Bearing Steel Flat Bar:

Cold drawing is usually a process of forcibly drawing the material through the hard alloy wire drawing die hole, which is stronger than pure drawing.The cold drawn carbon steel round bar is not only stretched longitudinally, but also subjected to lateral extrusion at the same time. After one or more times of cold drawing, the internal lattice slips, the tensile strength can be increased by 50% to 90%, and the hardness is increased, but the plasticity is significantly reduced.

Cold drawn carbon steel bars are used for applications in which a superior surface finish and exact dimensions are essential. Round steel bars are one of the most commonly used manufacturing and machining because of its strength, finish, versatility, and affordability. Also, they can be cut and machined into tools easily.

Finished goods packing