- Home

- >

- Products

- >

- Cold Drawn Flat Bar

- >

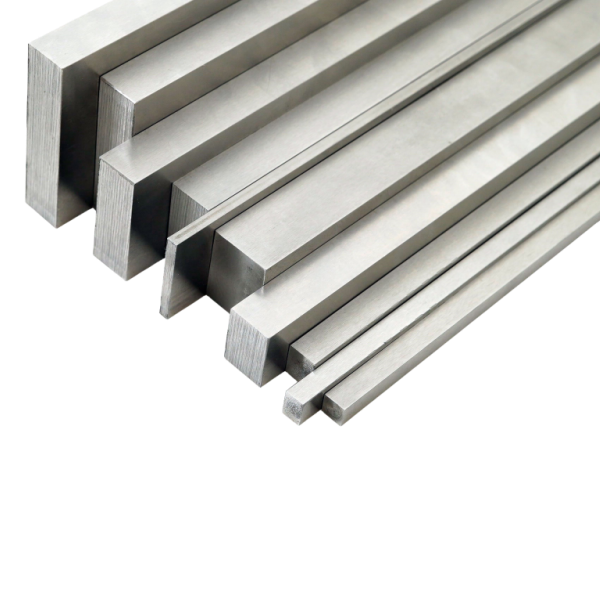

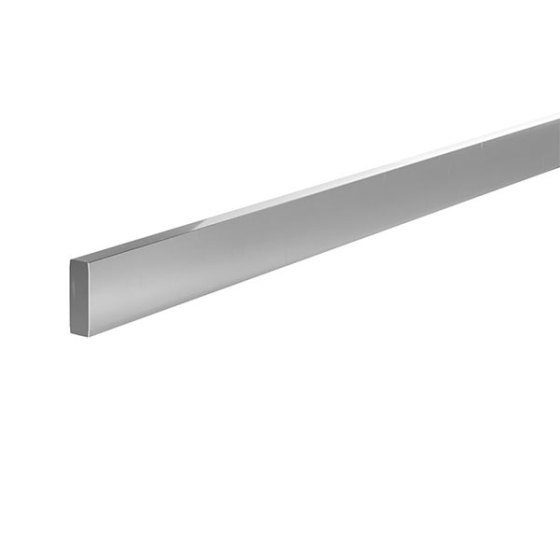

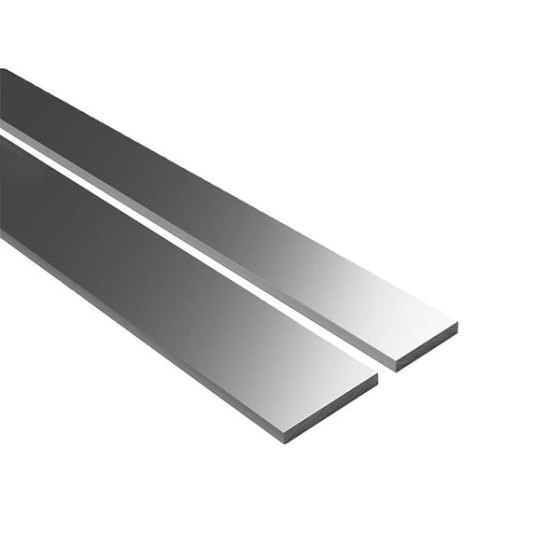

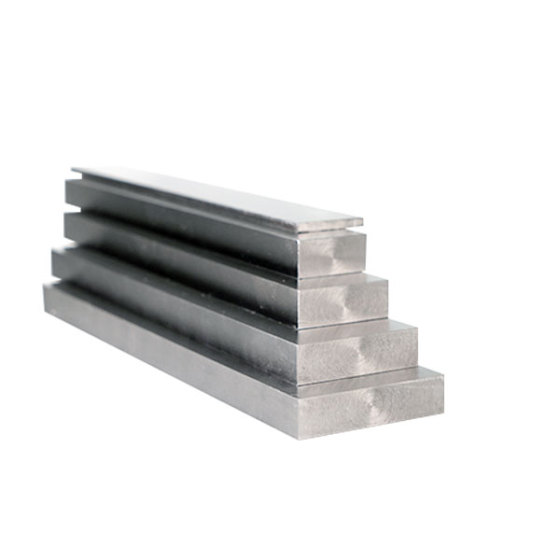

Cold Drawn Flat Bar

1. Cold Drawn Bearing Steel Flat Bar has high contact fatigue strength, which can well extend the service life of the bearing.

2. Cold Drawn Bearing Steel Flat Bar has strong wear resistance and high hardness.

3. Cold Drawn Bearing Steel Flat Bar has strong anti-rust performance and strong processing performance.

- Information

- Download

Material introduction of 4130 cold drawn flat bar:

Cold Drawn Alloy Steel Flat Bar is mainly made of carbon structural steel, high-quality carbon structural steel, and low-alloy high-strength structural steel.4140 cold drawn flat bar is widely used in mechanical processing, construction engineering, bridge engineering, petrochemical industry, aircraft manufacturing, automobile manufacturing, aerospace, etc.

Specifications of Cold Drawn Alloy Steel Flat Bar:

| Product Name | Cold drawn alloy steel flat bar |

| Materials Grade | 4140,4135,4330,8620,35CrMo,42CrMo,50CrV |

| Standard | AISI, ASTM,JIS, GB,EN |

| Size | 8x10~50x60mm |

| Length | 3000mm-12000mm or as client's request |

| Tolerance | ±1% |

| Technology | Cold drawn,Hot rolled |

| Packing | Seaworthy packing |

| Payment Term | L/C,T/T(30% deposit) |

| Lead Time | 20 days or to be negotiated |

| MOQ | ≤1000kgs |

| Supply Ability | 10000 Ton Per year |

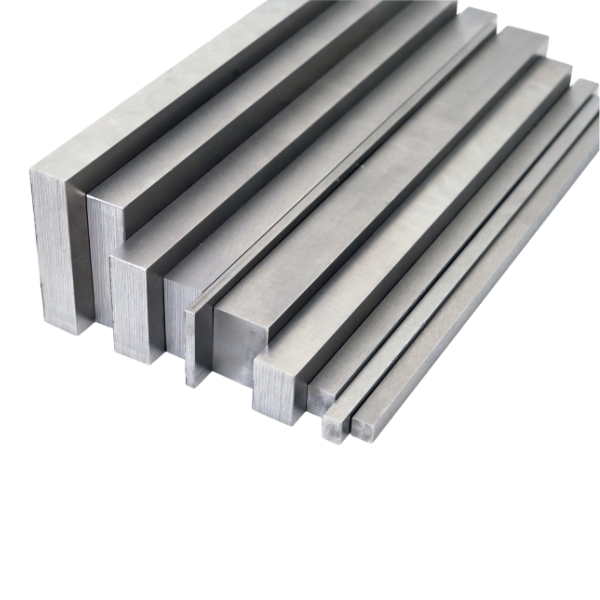

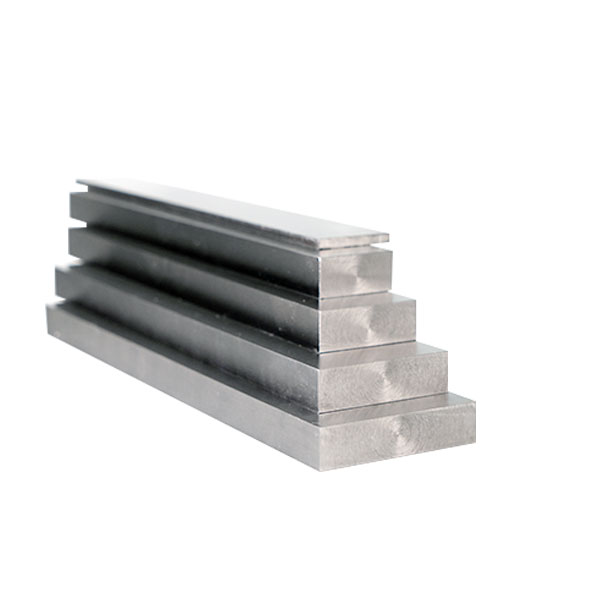

Features of Cold Drawn Alloy Steel Flat Bar:

1. The raw materials of 4145 cold drawn flat bar are all made of high-quality raw materials, which meet the standards of our country and are the same as thick steel plates.

2. Cold Drawn Alloy Steel Flat Bar has a full range of specifications, and the product specifications are relatively dense, which can meet the needs of users, replace the use of sheet steel, and can be directly welded without cutting.

3. The thickness of 4330 cold drawn flat bar is large, the overall width is narrow, the cross-sectional specification is standard, and the surface is smooth.

4. The two sides of 8620 cold drawn flat bar are straight with clear edges and corners.

5. The two-stage vertical rolling in fine rolling ensures good straightness of both sides, good edge process performance, and is durable, corrosion-resistant, and has a long service life.

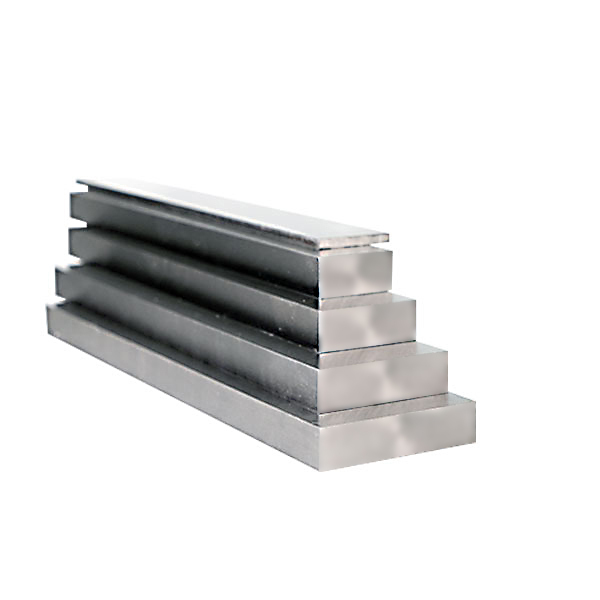

Process Introduction of Cold Drawn Alloy Steel Flat Bar:

Cold drawing is usually a process of forcibly drawing the material through the hard alloy wire drawing die hole, which is stronger than pure drawing.The cold drawn carbon steel round bar is not only stretched longitudinally, but also subjected to lateral extrusion at the same time. After one or more times of cold drawing, the internal lattice slips, the tensile strength can be increased by 50% to 90%, and the hardness is increased, but the plasticity is significantly reduced.

Cold drawn carbon steel bars are used for applications in which a superior surface finish and exact dimensions are essential. Round steel bars are one of the most commonly used manufacturing and machining because of its strength, finish, versatility, and affordability. Also, they can be cut and machined into tools easily.

Workshop

Laboratory