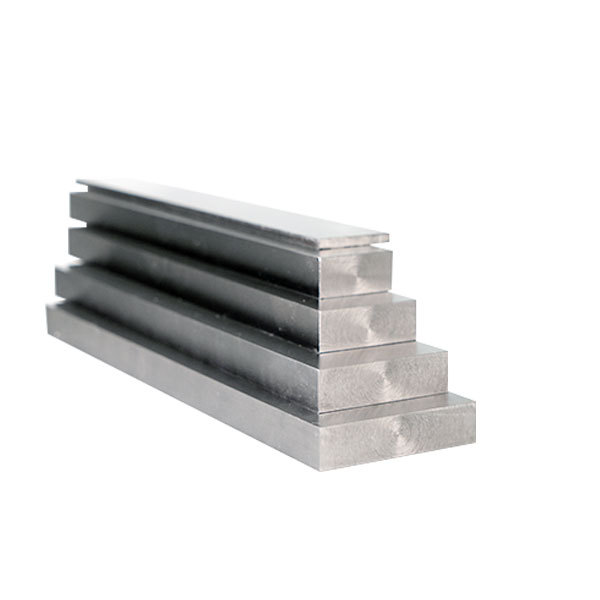

Cold Drawn Carbon Steel Flat Bar

1. Cold Drawn Carbon Steel Flat Bar can be produced in fixed thickness, fixed width, and fixed length according to user needs, which reduces cutting for users, saves processes, reduces labor and material consumption, and also reduces processing loss of raw materials, saving Time, labor and material saving.

2. Cold Drawn Carbon Steel Flat Bar uses cemented carbide molds and has professional mold repair personnel to ensure accurate tolerances.

3. Due to the high accuracy and good surface condition, Cold Drawn Carbon Steel Flat Bar can be used directly, such as spraying, sanding, bending, drilling, and can also be directly electroplated after fine drawing according to actual requirements, eliminating a lot of machining Time and save the cost of configuring processing machinery.

- Information

- Download

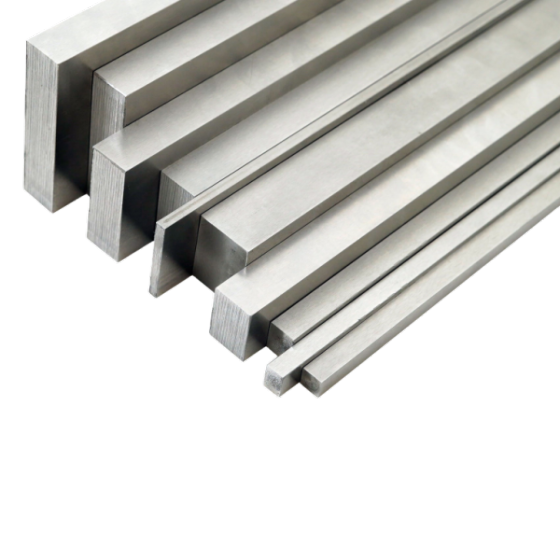

Main uses of Cold Drawn Carbon Steel Flat Bar:

1. Application of 1045 cold drawn flat bar in mechanical equipment: woodworking machinery, ceramic machinery, papermaking machinery, glass machinery, food machinery, construction machinery, plastic machinery, textile machinery, jacks, hydraulic presses, etc.;

2. Application of 1020 cold drawn flat bar in electrical product components: motor shaft, fan shaft, sewing machine shaft, etc.;

3. The application of 1050 cold drawn flat bar in hardware spare parts: such as guide rails, machine keys, nuts, screws, round nails, hexagonal nails, octagonal nails and various standard parts of different specifications, etc.; automobile and motorcycle spare parts, etc.

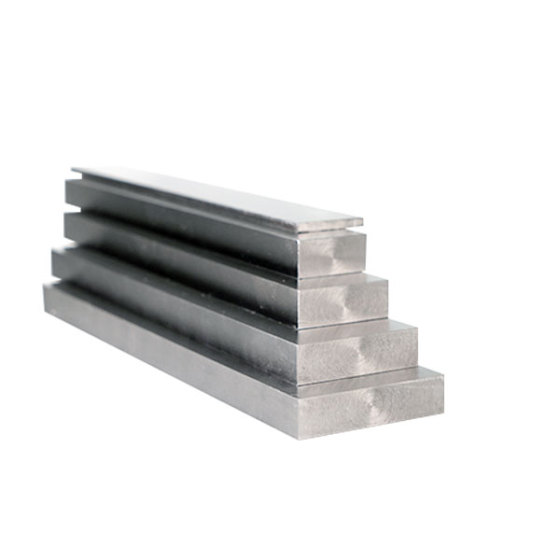

Main specifications of Cold Drawn Carbon Steel Flat Bar:

| Product Name | Cold drawn carbon steel flat bar |

| Materials Grade | 1045,1050,1020,12L14,1215,45#,20#,50# |

| Standard | AISI, ASTM,JIS, GB,EN |

| Size | 8x10~50x60mm |

| Length | 3000mm-12000mm or as client's request |

| Tolerance | ±1% |

| Technology | Cold drawn, Hot rolled |

| Packing | Seaworthy packing |

| Payment Term | L/C,T/T(30% deposit) |

| Lead Time | 20 days or to be negotiated |

| MOQ | ≤1000kgs |

| Supply Ability | 10000 Ton Per year |

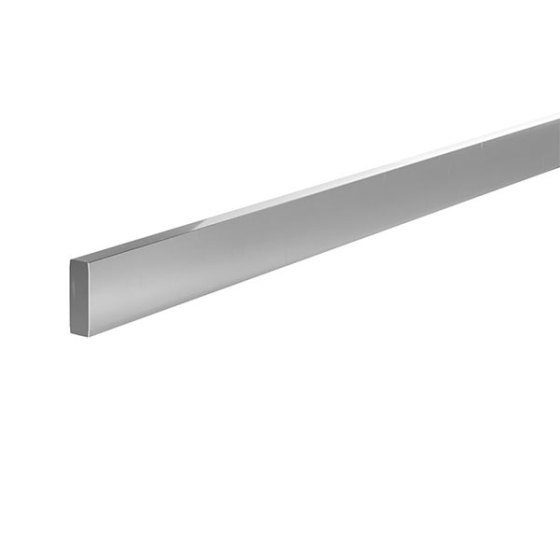

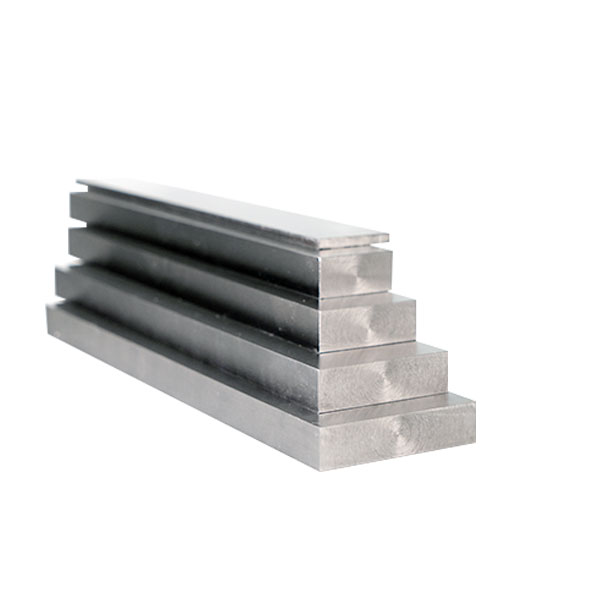

Advantages of Cold Drawn Carbon Steel Flat Bar:

1. Dachang raw materials: 1215 cold drawn flat bar is strictly selected, with high surface finish, good corrosion resistance and long service life.

2. Flat cut: 12L14 cold drawn flat bar has excellent processing equipment, good processing technology, smooth cut and no burr, and good mechanical properties.

3. High plasticity: Cold Drawn Carbon Steel Flat Bar has high plasticity and toughness, and is not easy to deform and break under strong pressure.

4. Processing and cutting: There are sufficient conventional stocks, rich specifications and materials, and cold-drawn alloy steel flat steel can be cut and processed on demand.

5. Cold Drawn Carbon Steel Flat Bar cold drawn steel with different cross-sectional shapes and different specifications and tolerances by designing molds of different shapes. Angles can be designed as right angles or rounded corners.

About us:

Shenyang Xindali Metal Technology Co., Ltd was established in 2015.The headquarters production base located at No. 9, Central Street, Yilu Industrial Park , Tieling City , Liaoning province covers area of 20,000 square meters. The company has passed ISO9001, IATF 16949,GJB9001B quality system certifications.

The construction of the factory area includes a cold-drawing heat treatment workshop, a silver-bright steel workshop, a joint drawing workshop, and a research and development center.

After years of development, with advanced equipment and perfect R&D and production mechanism, the company has developed into the largest special steel profile finishing enterprise specializing in the production of cold-drawn steel and silver-bright steel in Northeast China. The main products include: cold-drawn round steel, cold-drawn square steel, cold-drawn flat steel, cold-drawn hexagonal steel, cold-drawn profile, silver bright steel, etc. according to the American AISI/ASTM , China GB , Japanese JIS standards production.The products are widely used in military, aviation, automobile, industrial automation and other fields. Up to now, the company's market share in the field of military industry and auto parts leads the same industry, with an annual production capacity of more than 20,000 tons, and its technical process leads other processing enterprises.We always aim at honesty, altruism, concentration, brand maintenance, and is committed to providing customers with high-quality products and first-class services.