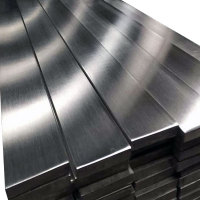

Cold Drawn Stainless Steel Flat Bar

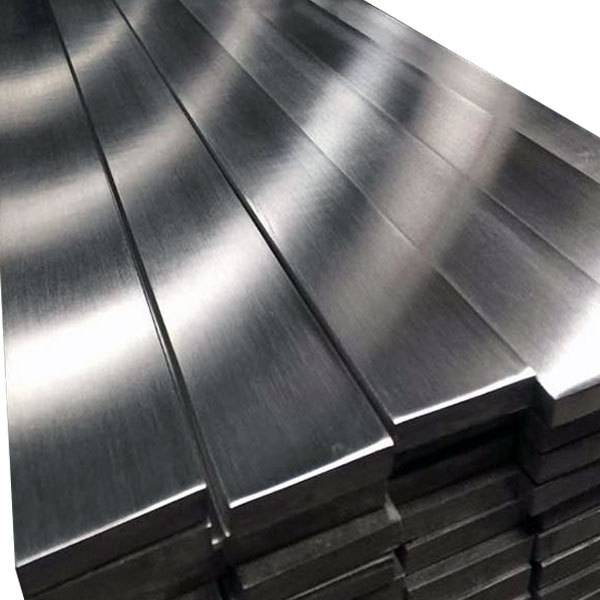

1. Cold Drawn Stainless Steel Flat Bar has excellent corrosion resistance, longer service life and low initial cost.

2. Cold Drawn Stainless Steel Flat Bar is made of high-quality materials, accurate in size, uniform in thickness, easy to bend and reprocess, and the products produced are of high quality.

3. The product surface of 310 cold drawn flat bar is smooth and clean, using precision cutting tools to make the surface smooth without scratches and burrs.

4. The grade and size of 304 cold drawn flat bar are diversified to meet various requirements.

- Information

- Download

Description of Cold Drawn Stainless Steel Flat Bar:

316 cold drawn flat bar is a flat bar made of stainless steel. 316 cold drawn flat bar can be semi-finished steel. There are cold drawn and polished stainless steel flat steel and hot rolled acid white and sandblasted stainless steel flat steel. The raw material billet for the production of stainless steel flat steel is stainless steel square billet, and the finished stainless steel flat steel is delivered in the state of hot rolling, normalizing or hot rolling pickling (or re-sand blasting), cold drawing and polishing. Both sides are equal in width.

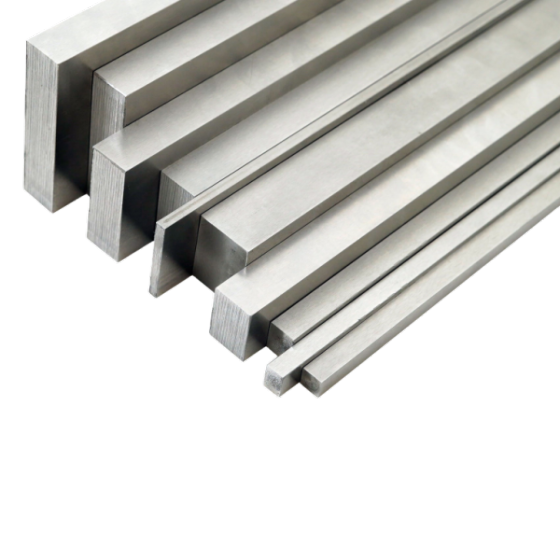

Main specifications of Cold Drawn Stainless Steel Flat Bar:

| Product Name | Cold drawn stainless steel flat bar |

| Materials Grade | 304,316,316L,321,420,9Cr18 |

| Standard | AISI, ASTM,JIS, GB,EN |

| Size | 8x10~50x60mm |

| Length | 3000mm-12000mm or as client's request |

| Tolerance | ±1% |

| Technology | Cold drawn,Hot rolled |

| Packing | Seaworthy packing |

| Payment Term | L/C,T/T(30% deposit) |

| Lead Time | 20 days or to be negotiated |

| MOQ | ≤1000kgs |

| Supply Ability | 10000 Ton Per year |

Application fields of Cold Drawn Stainless Steel Flat Bar:

Widely used in petroleum, food, chemical industry, construction, electric power, nuclear energy, energy, machinery, biology, papermaking, shipbuilding, boilers and other fields.

Key Benefits of Cold Drawn Stainless Steel Flat Bar:

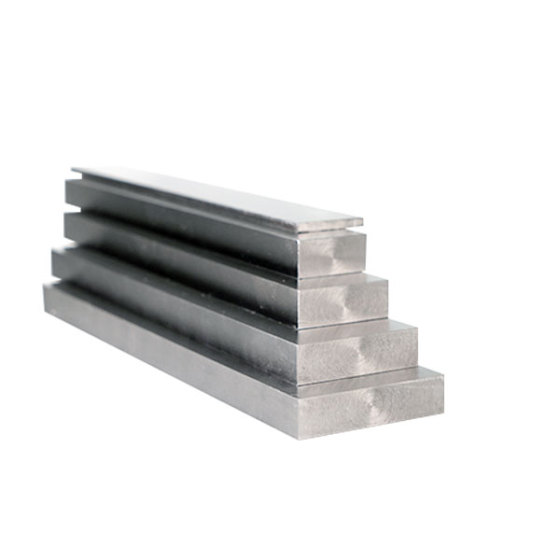

The raw materials of 420 cold drawn flat bar are all made of high-quality raw materials, which meet the standards of our country and are the same as thick steel plates.

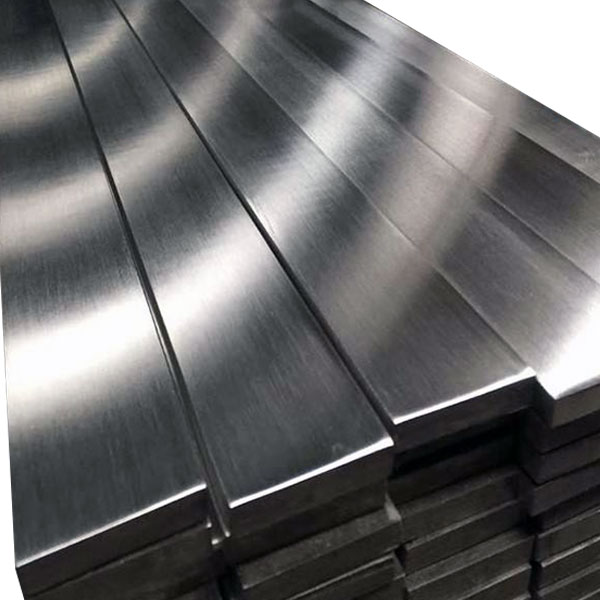

The thickness of 321cold drawn flat bar is large, the overall width is narrow, and the cross-sectional specification is standard. Technically, the high-pressure water descaling process is adopted for the second time to ensure the surface of the stainless steel plate is clean and beautiful.

The production standard of 316 cold drawn flat bar is accurate, and the same range is better than that of thick steel plate; the cold drawn flat steel product is vertical and the plate shape is good.

316 The sides of the cold drawn flat bar are straight with clear edges and corners. The two-stage vertical rolling in fine rolling ensures good straightness of both sides, good edge process performance, and is durable, corrosion-resistant, and has a long service life.

Company Introduction:

Xindali Metal Technology Co., Ltd was established in 2015.The headquarters production base located at No. 9, Central Street, Yilu Industrial Park , Tieling City , covers an area of 20,000 square meters. The construction of the factory area includes a cold-drawing heat treatment workshop, a silver-bright steel workshop, a joint drawing workshop, and a research and development center.

After years of development, with advanced equipment and perfect R&D and production mechanism, the company has developed into the largest special steel profile finishing enterprise specializing in the production of cold-drawn steel and silver-bright steel in Northeast China. The main products include: cold-drawn round steel, cold-drawn square steel, cold-drawn flat steel, cold-drawn hexagonal steel, cold-drawn profile, silver bright steel, etc. The products are widely used in military, aviation, automobile, industrial automation and other fields. Up to now, the company's market share in the field of military industry and auto parts leads the same industry, with an annual production capacity of more than 20,000 tons, and its technical process leads other processing enterprises.

Production Process