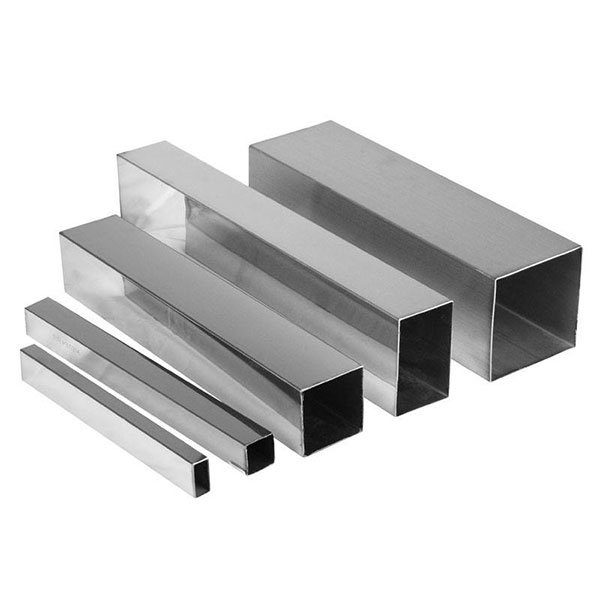

Cold Drawn Spring Square Steel

1. Cold Drawn Spring Square Steel has higher fatigue limit and higher tensile strength.

2. Cold Drawn Spring Square Steel has certain impact toughness and sufficient plasticity.

3. Cold Drawn Spring Square Steel has good hardenability and low decarburization sensitivity, which greatly reduces the elastic limit.

- Information

- Download

Introduction of Cold Drawn Spring Square Steel:

6150 cold drawn square steel refers to the steel spring steel specially used to manufacture springs and elastic elements due to its elasticity in the quenched and tempered state. It belongs to steel for mechanical structures. Steel that requires particularly strict control of quality and performance during the process. The elasticity of steel depends on its ability to deform elastically, that is, within a specified range, the ability to deform elastically allows it to withstand a certain load without permanent deformation after the load is removed .

Applications of Cold Drawn Spring Square Steel:

Cold Drawn Spring Square Steel can be used in mechanical equipment, construction works, transportation, energy. Such as pressure regulating speed spring, force measuring spring, round and square coil spring on general machinery or drawn steel wire as spring on small machinery, high wear resistance parts.

Specifications of Cold Drawn Spring Square Steel:

| Product Name | Cold drawn spring steel square bar |

| Materials Grade | 6150,9260H |

| Standard | AISI, ASTM,JIS, GB,EN |

| Size | S8-S50 |

| Length | 3000mm-12000mm or as client's request |

| Tolerance | ±1% |

| Technology | Cold drawn,Hot rolled |

| Packing | Seaworthy packing |

| Payment Term | L/C,T/T(30% deposit) |

| Lead Time | 20 days or to be negotiated |

| MOQ | ≤1000kgs |

| Supply Ability | 10000 Ton Per year |

Pros of Cold Drawn Spring Square Steel:

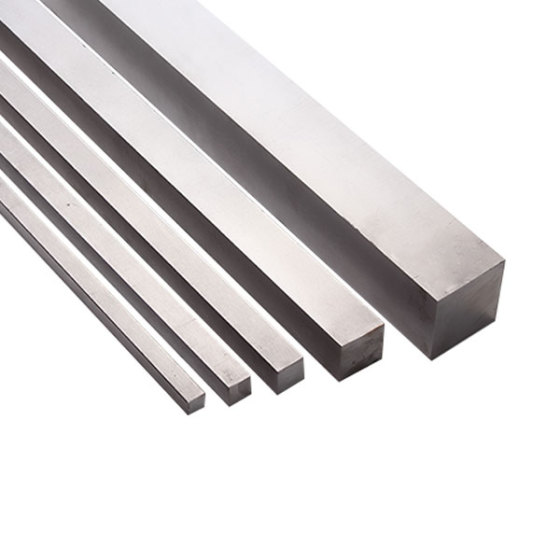

9260H cold drawn square steel has excellent comprehensive properties, excellent metallurgical quality (high purity and uniformity), good surface quality (strict control of surface defects and decarburization), precise shape and size.

9260H cold drawn square steel has high elastic limit and high yield ratio to avoid permanent deformation of spring steel under high load.

The addition of vanadium refines the grains of steel, reduces overheating sensitivity, and improves strength and toughness.

Cold Drawn Spring Square Steel is a relatively high-grade spring steel, used as a high-load important spring steel with a large cross-section and valve spring steel, piston spring steel, and safety valve spring steel with a working temperature <300 °C.

Good Surface Quality

Before cold drawing, the material needs to be pickled to remove rust, and through phosphating and saponification treatment to form a dense metal soap film on the outer surfaces to reduce the friction between the material and the mold, and finally through the cold extrusion technology to make the surface of cold drawn steel becomes bright and smooth.

High Accuracy

According to the design plan, cold-drawn steel has different shapes of abrasive tools, and cold-drawn different cross-sectional shapes, different specifications, and size tolerances. The angle of view can be designed as an oblique angle or arc.Cold-drawn steel uses high-quality cemented carbide molds to to ensure precise and uniform dimensional tolerances.

Save Production Time

Due to its good surface quality and high dimensional accuracy, the surface layer grows steadily, and cold drawn products can be applied immediately, such as painting, sanding, bending, punching, or electroplating process immediately after fine drawing according to specific regulations,eliminating a lot of mechanical processing time and save the cost of equipping processing equipment.

Save Raw Material

The cold drawing process is to transform the raw materials to the required shape, specifications and dimensional tolerances by hot forging. The loss of raw materials is very small.Relatively, using traditional CNC lathes to process the raw materials lost in drilling,and cutting materials, the saving of raw materials is obvious,especially when the amount of raw materials used is large, more raw materials will be saved considerably.