Cold Drawn Bearing Square Steel

1. Cold Drawn Bearing Square Steel has strong wear resistance and high elastic limit.

2. Cold Drawn Bearing Square Steel has high contact fatigue strength and long service life.

3. Cold Drawn Bearing Square Steel has good impact toughness and fracture toughness.

- Information

- Download

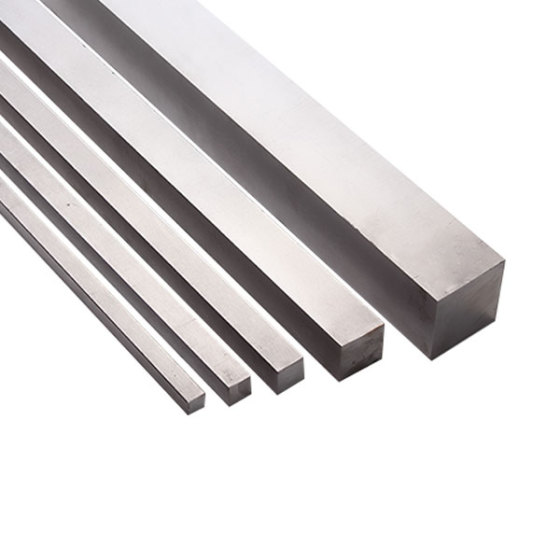

Introduction of Cold Drawn Bearing Square Steel:

Bearing steel is made of high-carbon chromium steel, which is generally used to make balls, rollers, and bearing rings and other accessories. 52100 cold drawn square steel has high hardness, excellent wear resistance, and balanced chemical composition. It has strict requirements on the distribution of various substances inside, especially the layout of carbides. It is one of the strictest in all types of steel production.

Application of Cold Drawn Bearing Square Steel:

GCr15 cold drawn square steel can be used in mechanical equipment, automobile industry, aviation equipment, shipbuilding and chemical industry, etc.

Main specifications of Cold Drawn Bearing Square Steel:

| Product Name | Cold drawn bearing steel square bar |

| Materials Grade | 52100, GCr15,GGr15SiMn, SUJ2 |

| Standard | AISI, ASTM,JIS, GB,EN |

| Size | 8X8~150X150mm |

| Length | 3000mm-12000mm or as client's request |

| Dia Tolerance | ±1% |

| Technology | Cold drawn,Hot rolled |

| Packing | Seaworthy packing |

| Payment Term | L/C,T/T(30% deposit) |

| Lead Time | 20 days or to be negotiated |

| MOQ | ≤1000kgs |

| Supply Ability | 10000 Ton Per year |

SUJ2 cold drawn square steel has high compressive strength and fatigue limit, high hardness, high wear resistance and certain toughness, good hardenability, and extremely strict control of sulfur and phosphorus. It is a high-grade high-quality steel.

Bearings can bear radial and axial loads at the same time, so the structure of bearings can be much simpler than that of multiple sets of combined bearings.

GGr15SiMn cold drawn square steel specifically has the characteristics of good dimensional stability and good cold and hot processing performance.

It can be used in high-precision and high-rigidity occasions where the size of the space condition is small.

Company Introduction:

Xindali Metal Technology Co., Ltd was established in 2015.The headquarters production base located at No. 9, Central Street, Yilu Industrial Park , Tieling City , covers an area of 20,000 square meters. The construction of the factory area includes a cold-drawing heat treatment workshop, a silver-bright steel workshop, a joint drawing workshop, and a research and development center.

After years of development, with advanced equipment and perfect R&D and production mechanism, the company has developed into the largest special steel profile finishing enterprise specializing in the production of cold-drawn steel and silver-bright steel in Northeast China. The main products include: cold-drawn round steel, cold-drawn square steel, cold-drawn flat steel, cold-drawn hexagonal steel, cold-drawn profile, silver bright steel, etc. The products are widely used in military, aviation, automobile, industrial automation and other fields. Up to now, the company's market share in the field of military industry and auto parts leads the same industry, with an annual production capacity of more than 20,000 tons, and its technical process leads other processing enterprises.

Production Process