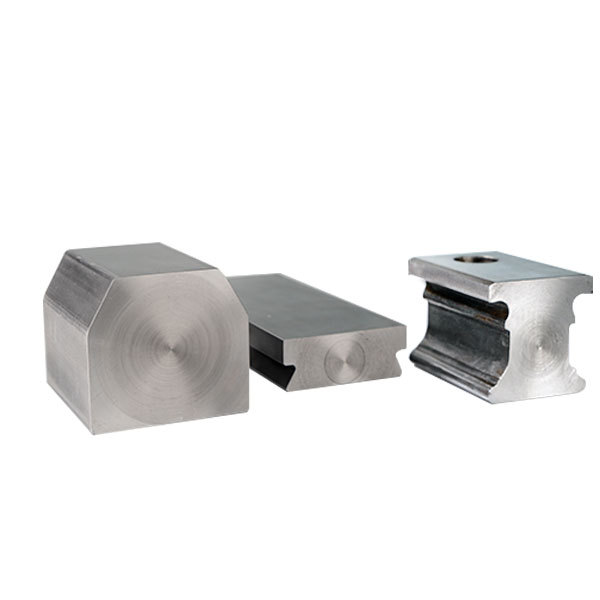

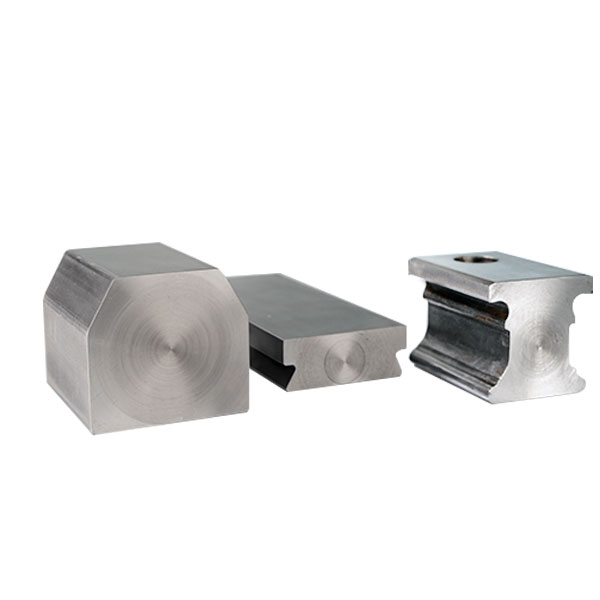

Cold Drawn Spring Steel Profile

1. 6150 cold drawn profiles cold-drawn spring steel profile is a highly durable and flexible metal, very suitable for construction projects.

2. The high tensile strength of 9260H cold drawn profiles makes it suitable for heavy-duty applications in manufacturing.

3. 9260H cold drawn profiles has anti-rust performance, which is very suitable for outdoor use.

- Information

- Download

Advantages of Cold Drawn Spring Steel Profile:

6150 cold drawn profiles has excellent fatigue resistance, even in multiple tension and compression cycles.

9260H cold drawn profiles has excellent fatigue resistance and maintains strength even after multiple tension and compression cycles.

Cold Drawn Spring Steel Profile is adaptable and can be customized in shape and size.

The ductility of the 9260H cold drawn profiles allows easy forming, bending or cutting without affecting strength.

9260H cold drawn profiles is recyclable and environmentally friendly, so it is the choice of sustainable development.

Main specifications of Cold Drawn Spring Steel Profile:

| Product Name | Cold drawn Spring Steel Profile |

| Materials Grade | 52100, GCr15,GGr15SiMn, SUJ2 |

| Standard | AISI, ASTM,JIS, GB,EN |

| Shape | as client's request |

| Length | 3000mm-12000mm or as client's request |

| Tolerance | ±1% |

| Technology | Cold drawn,Hot rolled |

| Packing | Seaworthy packing |

| Payment Term | L/C,T/T(30% deposit) |

| Lead Time | 20 days or to be negotiated |

| MOQ | ≤1000kgs |

| Supply Ability | 10000 Ton Per year |

Introduction of Cold Drawn Spring Steel Profile:

Cold Drawn Spring Steel Profile is a steel that is drawn through a series of dies to achieve the desired shape and size. During this process, the steel is subjected to high pressure, which strengthens the steel and increases its durability. Cold Drawn Spring Steel Profile is known for its excellent mechanical properties and impressive resilience.

Our machinery and equipment

The company is now equipped with 7 sets of straight drawing machines, 7 sets of automatic electric annealing furnaces, 2 sets of straight shot blasting machines, 3 sets of round shot blasting machines, 4 sets of centerless lathes, and 5 sets of Φ10-Φ50 straightening and rolling machines. Taiwan, 2 Φ20-Φ80 straightening and rolling machines, 1 Japanese ten-roll straightening machine, 10 centerless grinding machines and other equipment. It also has an 8-ton combined drawing production line and a 10-ton combined drawing two independent production lines collection, etc.

Production processes

The production process is material, heat treatment, shot blasting, cold-drawing, straightening, cutting, grinding, inspection, and package.