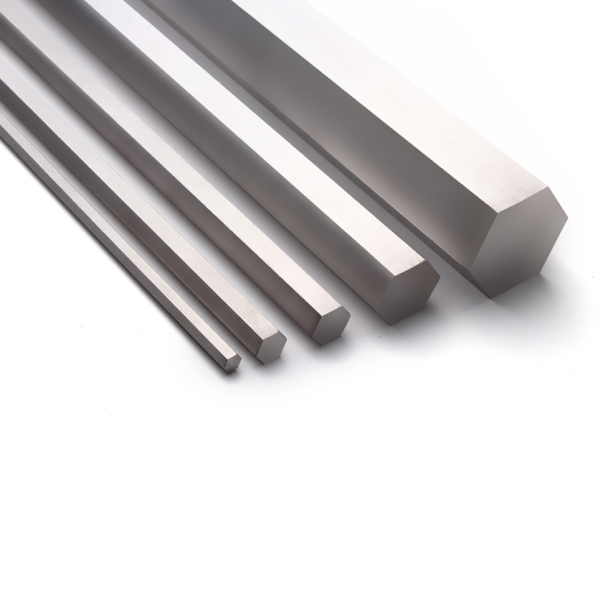

Cold Drawn Hexagonal Steel

1. 310 cold drawn hexagonal Steel is not easy to wear and rust.

2. 310 cold drawn hexagonal Steel supports processing customization.

3. 310 cold drawn hexagonal Steel is suitable for construction, chemical industry and machinery.

- Information

- Download

Features of Cold Drawn Bearing Steel Round Bar:

1. Diversity of shapes and specifications: By designing molds of different shapes, 304 cold drawn hexagonal Steel with different cross-sectional shapes, different specifications and tolerances can be drawn at right angles or rounded corners.

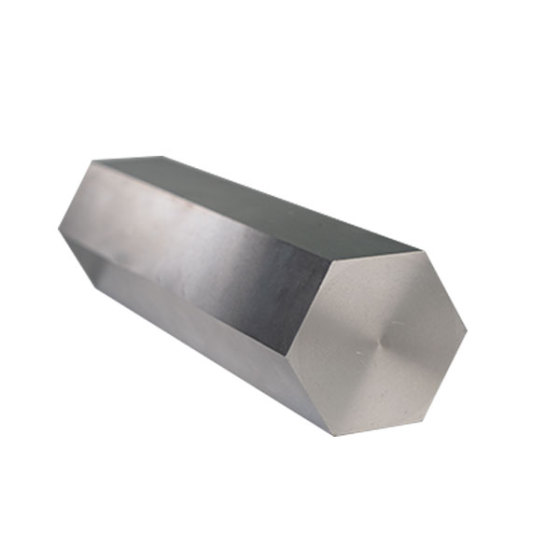

2. 316 cold drawn hexagonal Steel is high-precision: use high-quality hard alloy molds to ensure accurate tolerance range of products;

3. The surface finish of 321cold drawn hexagonal Steel is good: the advanced cold extrusion technology makes the surface of cold drawn steel smooth and bright.

4. The 420 cold drawn hexagonal Steel material has a high yield: the cold drawing process is to cold draw and extrude the raw material to achieve the required shape, specification and tolerance. The yield of raw materials is high and the consumption is low. Compared with the materials consumed by traditional lathe processing, 420 cold drawn hexagonal Steel saves considerable materials, and the overall cost is more ideal.

5. The processing time of 321cold drawn hexagonal Steel saves processing machinery: Due to the accurate precision and good surface condition, cold drawn steel can be used directly, such as spraying, grinding, bending, rotating holes, etc., or it can be directly drawn after fine drawing according to actual needs Electroplating saves a lot of processing time and saves the cost of configuring processing machinery.

Specifications of Cold Drawn Bearing Steel Round Bar:

| Product Name | Cold drawn stainless steel Hexagonal |

| Materials Grade | 304,316,316L,321,420,9Cr18 |

| Standard | AISI, ASTM,JIS, GB,EN |

| Size | S8-S50 |

| Length | 3000mm-12000mm or as client's request |

| Dia Tolerance | ±1%, +0.5mm/-0(dia),+5mm/-0(L) |

| Technology | Cold drawn,Hot rolled |

| Packing | Seaworthy packing |

| Payment Term | L/C,T/T(30% deposit) |

| Lead Time | 20 days or to be negotiated |

| MOQ | ≤1000kgs |

| Supply Ability | 10000 Ton Per year |

Xindali Section Steel was established in 2015.The headquarters production base located at No. 9, Central Street, Yilu Industrial Park , Tieling City , covers an area of 20,000 square meters. The construction of the factory area includes a cold-drawing heat treatment workshop, a silver-bright steel workshop, a joint drawing workshop, and a research and development center.

After years of development, with advanced equipment and perfect R&D and production mechanism, the company has developed into the largest special steel profile finishing enterprise specializing in the production of cold-drawn steel and silver-bright steel in Northeast China. The main products include: cold-drawn round steel, cold-drawn square steel, cold-drawn flat steel, cold-drawn hexagonal steel, cold-drawn profile, silver bright steel, etc. The products are widely used in military, aviation, automobile, industrial automation and other fields. Up to now, the company's market share in the field of military industry and auto parts leads the same industry, with an annual production capacity of more than 20,000 tons, and its technical process leads other processing enterprises.

Workshop

Laboratory